NXTmix is a cutting-edge levitation-based mixing technology designed for various single-use applications in bioprocessing. It offers flexibility and complies with cGMP standards, accommodating volumes up to 1000L. The system incorporates levitation technology, allowing customization and easy mixing of powder-liquid or liquid-liquid applications. With a wide range of volumes available, NXTmix is suitable for final formulation, buffer and media preparation, virus inactivation, and blending of intermediate products. The MagLev Mixer, based on magnetic levitation, eliminates wear and tear, providing a contact-free and particle-shedding-resistant solution. Its robust design enhances mixing efficiency and reduces shear, making it ideal for shear-sensitive products.

NXTmix is the next-generation levitation-based mixing technology designed to handle all your single-use mixing requirements from media & buffer preparation, intermediate process mixing, final formulation and filling application. A highly flexible and cGMP complaint system allows you to use volumes commonly used in manufacturing processes of up to 1000L.

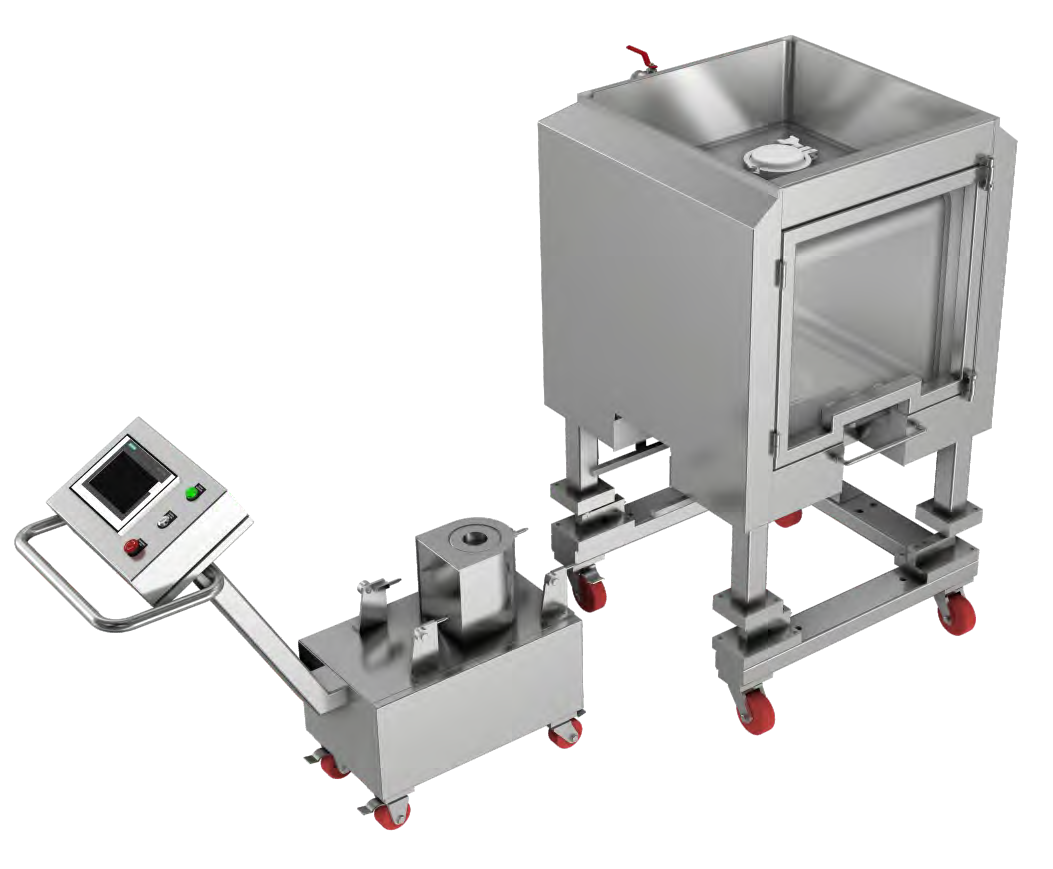

The NXTmix system incorporates levitation technology for a single-use mixing system fitted into either a plastic tote with a trolley or stainless steel tanks. NXTmix offers complete flexibility with options to customize, providing users with easy mixing of powder-liquid or liquid-liquid applications.

1) Various Applications:

NXTmix is available in a wide range of volumes starting from 50L, 100L, 200L, 500L and 1000L which are suitable for various applications such as:

- Final Formulation

- Buffer Preparation

- Media Preparation

- Preparation of Semi-Finished Products

- Virus Inactivation

- Blending of Purified Intermediate Products

2) Meg Lev Mixer

PharmNXT Biotech has developed an innovative mixer system based on magnetic levitation, eliminating the need for bearings and seals. The mixer impeller is suspended contact-free inside a sealed cup and driven by the magnetic field of the motor. Made from biocompatible gamma sterilizable polypropylene, the system reduces the risk of particle shedding. The design increases mixing efficiency, reduces shear, and enables gentle mixing for shear-sensitive products. It allows for higher-capacity systems with linear scalability, making it ideal for bioprocessing and final formulation.

MORE SOLUTIONS

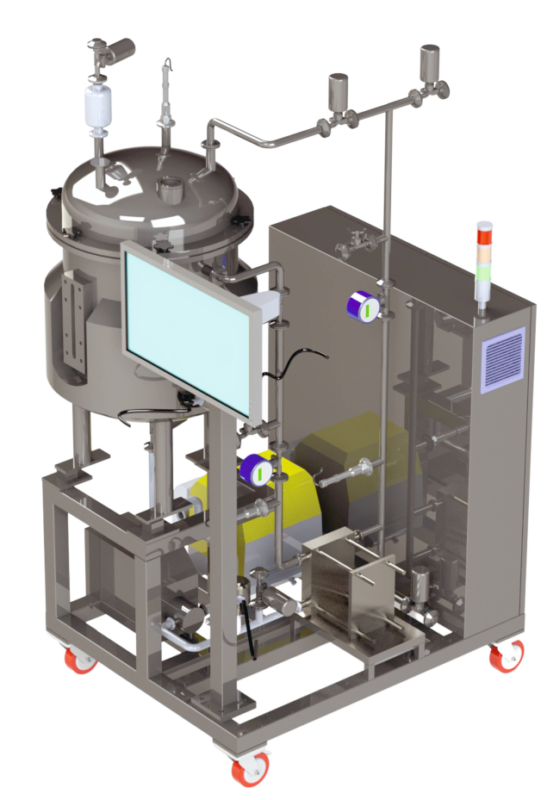

NXTtff

The NXT TFF system by PharmNXT Biotech is a system that’s perfect for running fully automated UF/DF processes at high capacity. It can handle any volume between 20L and 500L (200 g to 2.5 kg), and the compact system, has a low hold-up volume and the capacity to accommodate cassettes with surface area ranging from 0.5 to 2.5 m2

Chromatography Resins (Purolite)

The purification of commercially-available monoclonal antibodies (mAbs) on the market today is typically performed in three chromatography steps. Purolite offer industry-leading solutions for each step.

Protein A Affinity Chromatography

A Protein A affinity resin is utilized as an initial antibody capture step. Praesto Protein A resins deliver exceptionally high purity (>99%) and yield in a single, efficient step.

Cation Exchange Chromatography

A Sulphopropyl- (SP) functionalized cation exchange resin in ‘bind and elute’ mode is used to remove aggregates and HCP (Host Cell Proteins).

Anion Exchange Chromatography

A Quarternary Amine (Q) functionalized anion exchange resin is used in ‘flow-through’ mode to remove trace contaminates and ensure sufficient viral clearance.

NXTmfilt

Single-use technology continues to be adopted for many areas of bioprocessing. The use of automation provides additional benefits in manufacturing such as consistency in product quality, reduced labor costs, and reduction of operator errors.