PharmNXT Biotech team has vast experience of working with customers across industry segments, from process development to manufacturing. The experience of PharmNXT Biotech is enabling the scientists in the Biologics industry to develop their processes, perform mass balance calculations, define automation strategy keeping in view the recent data compliance requirements, do equipment sizing and perform tech transfer from PD to manufacturing, all this with high efficiency and economically.

Following are the services offered by PharmNXT Biotech for Process Engineering Consultancy:

-

- Process Development

- Mass Balance Calculations & Equipment Sizing

- Single Use equipment arrangement

- Overall Project Management

Process Engineering Consultancy Offering

Process

Development

- On-site support for process development

- QBD approach

- Scale-up requirements inbuilt from PD

- Using chemicals suitable for scale-up

- Process Parameter optimization making scale-up easy

- Complete Tech. transfer

Mass Balance and Equipment Sizing

- Mass Balance simulation based on customer data

- Buffer volume calculations

- Rate of buffer consumption

- Tank scheduling to optimize tank purchase

- Equipment sizing to meet current and future demands

- Facility fit where existing facilities to be used

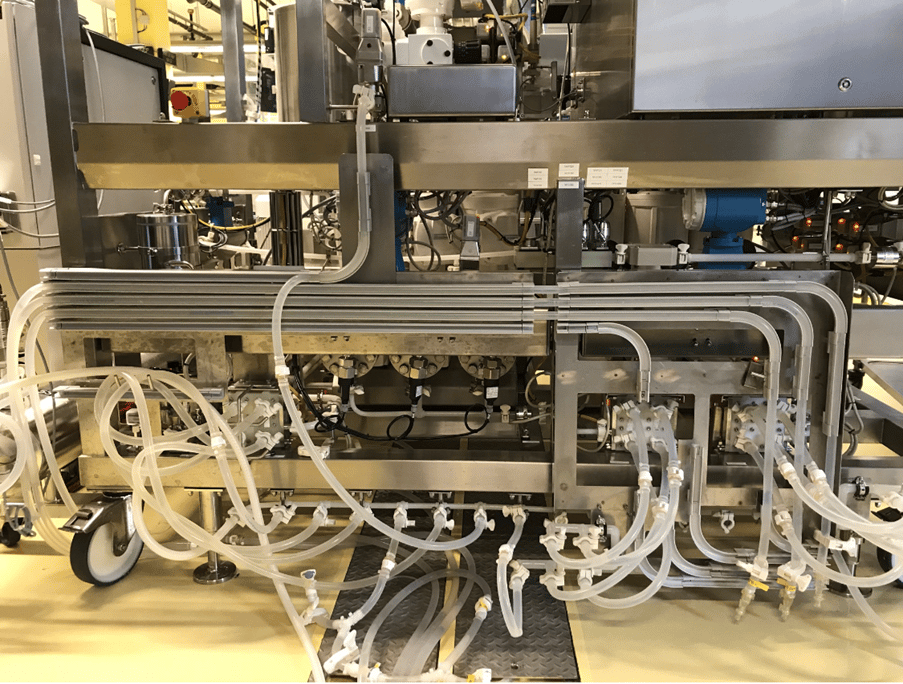

Single-Use Equipment Arrangement

- Single-use systems in manufacturing have changed the way facilities are built

- Philosophies of piping management, transfer between unit operations and between rooms have changed.

- PharmNXT Biotech has the experience and knowledge to design efficiently & economically

Overall Project Management

- Working with engg. consultant & process team to prepare URS, SOPs & Tech transfer docs

- Management of suppliers – Responsibilities from DQ to Qualification

- Perform equipment qualification – Turnkey or only supervision

- Support first few mfg. batches