Lab Working Cell Bank

A working cell bank (WCB) in mRNA production is a collection of cells derived from a single master cell bank and maintained under controlled conditions to ensure the stability and consistency of the cells. These cells are regularly tested for purity and identity to ensure they are free of contaminants. The WCB is subject to strict documentation and traceability requirements to ensure the quality and safety of the mRNA product. The WCB is used to generate mRNA for various downstream applications, such as gene therapy and vaccine production.

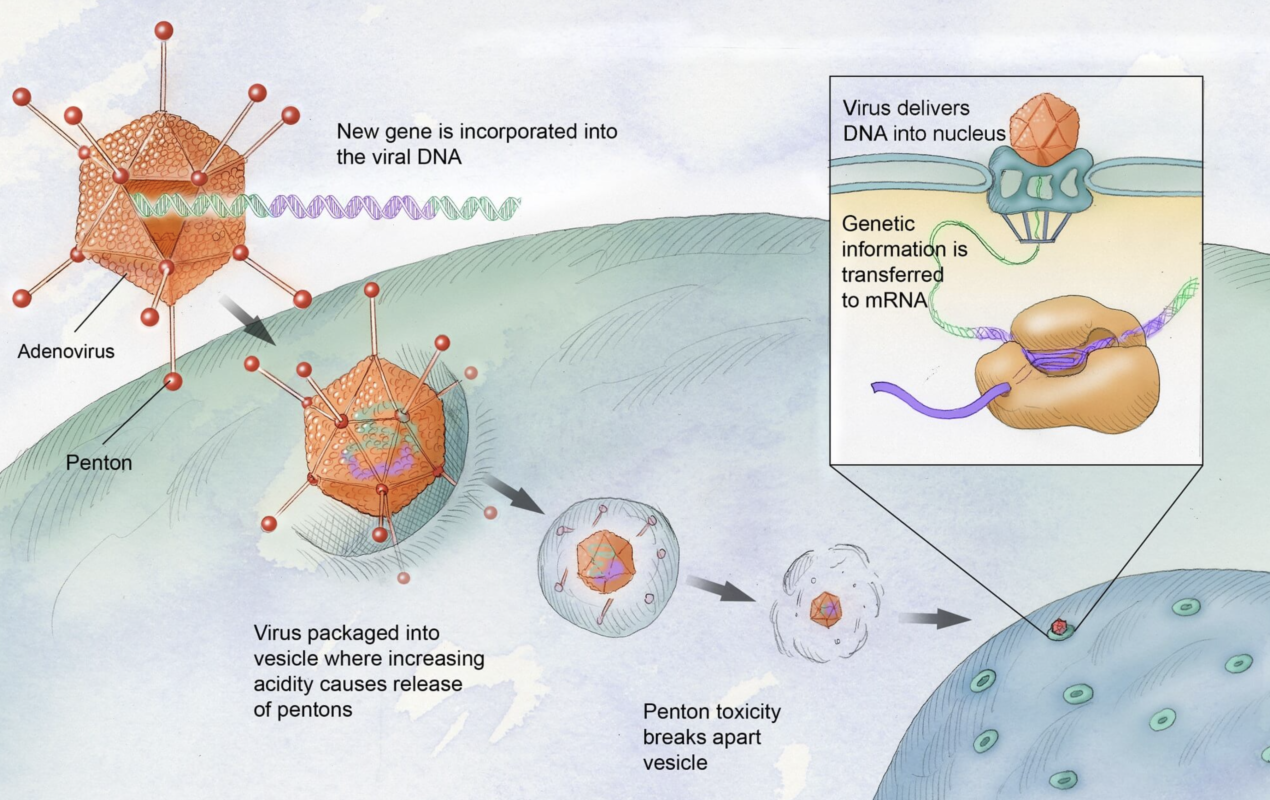

Upstream Process

The upstream processes in mRNA production involve preparing the mRNA template and producing the RNA polymerase enzyme for transcription. The mRNA template is chemically synthesized and modified for stability and translational efficiency. RNA polymerase is either purified from natural sources or produced recombinantly using bacterial or mammalian expression systems. The gene encoding the enzyme is cloned, transformed, and cultured to produce the enzyme, which is purified and tested for activity and purity. Upstream processes are crucial for producing high-quality mRNA, and any deviations could affect downstream processes and the final product’s quality and efficacy.

Downstream Process

The downstream processes of mRNA production involve purifying and testing the synthesized mRNA for quality, purity, and stability before it can be used in various applications such as gene therapy or vaccine production. The mRNA is purified using various methods to remove impurities, and it undergoes quality control tests to ensure its suitability for downstream applications. Once the mRNA passes all quality control tests, it can be formulated for use. Downstream processes are crucial for the successful production of high-quality mRNA, and any errors or deviations in this stage could impact the final product’s quality and efficacy.

Aseptic fill and finish

Aseptic fill and finish is the final step in mRNA production that involves filling purified mRNA into vials or cartridges under sterile conditions. The process includes vial washing, sterilization, filling, and sealing, all of which are carried out under aseptic conditions. The filled vials are inspected for defects and labeled with batch information and expiration dates. This step is critical to ensure the final product is sterile, safe, and effective for use in various applications.