SaniSure is a global leader in simplifying single-use systems for sterile drug and vaccine manufacturing and other biotech applications. With the combination of industry-leading single-use technology (SUT) companies (Cellon, Silicone Altimex, TBL Performance Plastics, GL Engineering and Sani-Tech West) in to SaniSure, our resources, capabilities, and ability to create value for customers is greater than ever and unmatched in the industry.

SaniSure’s core manufacturing capabilities include injection molding, injection-stretch blow molding, cleanroom assembly, tubing extrusion, fabrication, needle manufacturing, and other proprietary technologies. With a global footprint of 6 manufacturing sites, we provide an unrivaled level of vertical integration and supply- chain security. Our founding companies have been at the forefront of SUT innovation for decades and have supported many clients through all phases of drug and vaccine development and production.

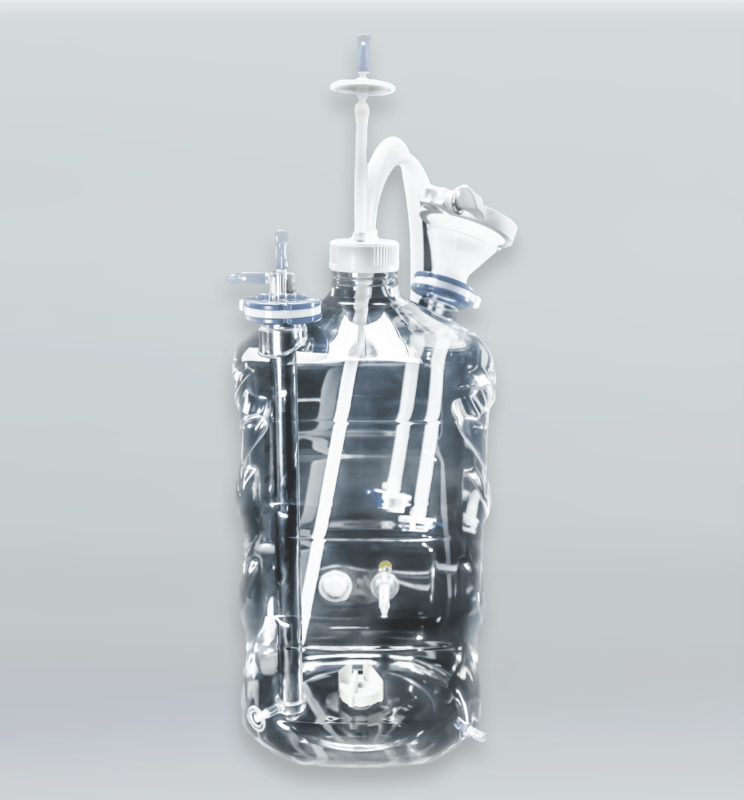

Mixed4Sure

Mixed4Sure™’ Bottom Mount is an aseptic, closed-system mixing platform that offers low shear and vigorous mixing. Available in several volumes and custom configurations, enabling it to be used in a variety of mixing steps.

Materials

-

- PharmaTainerTM: Polycarbonate (PC) or Polyethylene Tetraphthalate (PET)

- Cap2v8®: Polypropylene (PP)

- Last Drop™ dip tube: Polypropylene (PP)

- Impeller : PEEK & Polyphenylsulfone (PPSU)

- Powder Funnel Port: Polycarbonate

Packaging

-

- Double-bagged and labelled in an ISO Class 7 Cleanroom

Sterilization

-

- Gamma radiation compatible (@50kGys)

- Sterility assurance level 10-6

Applications

-

- Buffer & media preparation

- Ultrafiltration/diafiltration

- Resuspension/homogenization

- Compounding

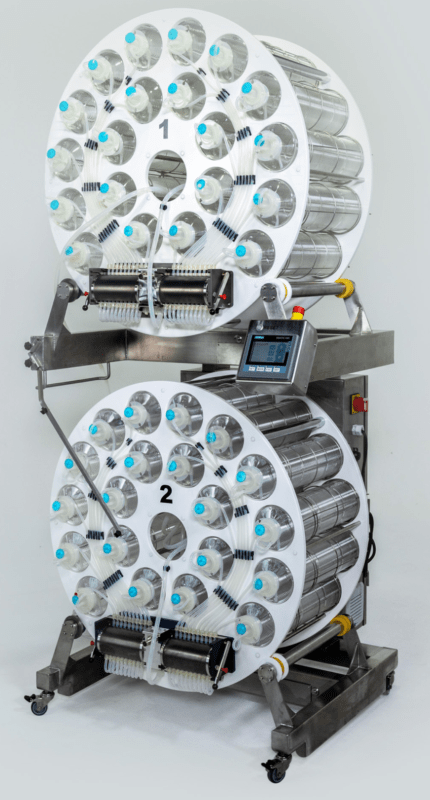

RC-40

One RC-40 system enables a single operator to complete a full roller bottle tissue culture protocol – seeding, media change, trypsinisation and harvest – for an equivalent of 200 standard roller bottles in less than two hours.

Specifications

Dimensions

-

- 1 98m High

- 0 95m Wide

- 0 71m Deep

Weight

-

- Machine only — 76Kg

- With packs loaded and 40L media — 132Kg

- With 40L media and Battery Backup — 144Kg

- Shipping weight — 110Kg

Rotor Speed

-

- 0.1 rpm to 12 rpm

Delivery Accuracy

-

- – < 0 +/5%

Power Supply

-

- Voltage – 90 to 264V ac

- Frequency – 47 to 63Hz

- Current – 5A

Environment

-

- Temperature — 0 to 40 deg _C

- Humidity — 0 to 95% RH, non-condensing

Cap2v8 Bottle Solutions

SaniSure® Cap2v8® (say “captivate”), was designed to capture, store and transfer high-purity fluid in a way that is unique to the single-use market. This product was created to solve a problem that you, our customers, had identified as preventing you from successfully making your product.