XELTA KoNXT

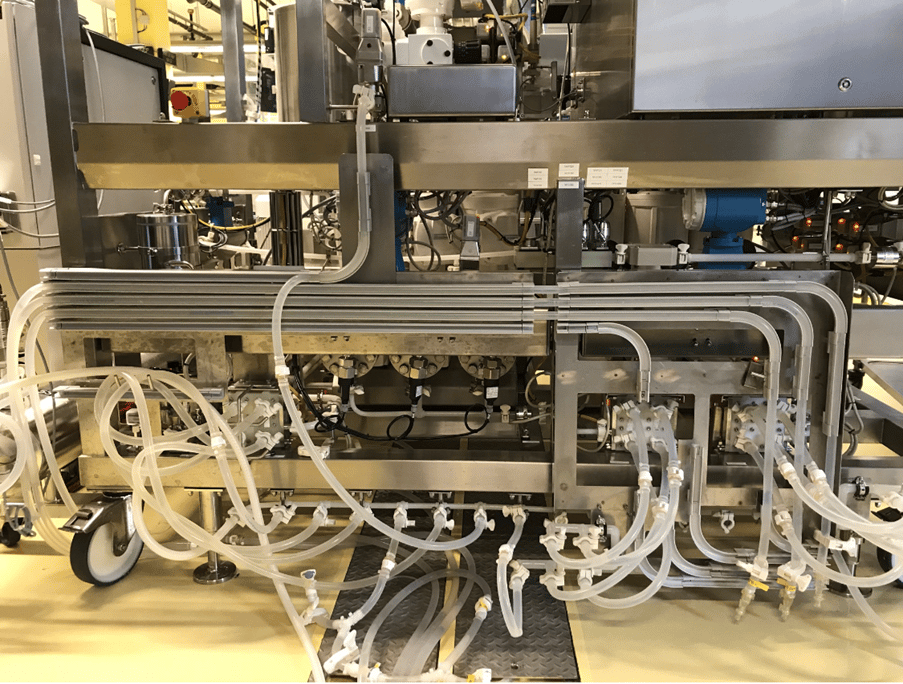

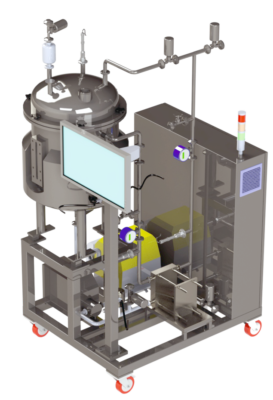

KoNXT is a range of Single Use assemblies designed as per the process needs of the customer. The customized KoNXT assemblies are carefully designed with a high degree of process knowledge to eliminate operator error and reduce the risk of contamination, XELTA KoNXT Single Use Assemblies minimize process risk in sterile operations by employing proven flexible connections. Through XELTA KoNXT assemblies, we’re able to provide maximum flexibility by allowing you to connect a wide variety of tube sizes and connectors into one easy solution. Optimized for single-use applications, XELTA KoNXT assemblies allow PharmNXT Biotech Team to create assemblies tailored to your specific requirements that result in reduced process risk.